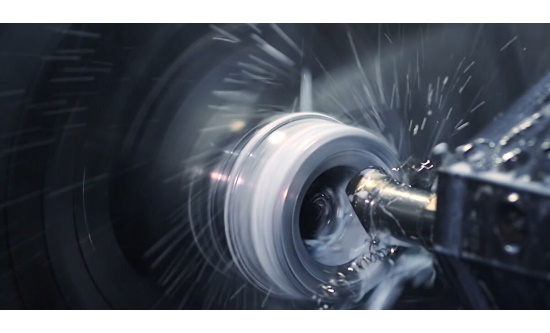

Efficiently applying coolant to the cutting zone is critical for many machining operations. Keeping chips out of the way so they aren’t being recut and managing the temperature of the work zone can reduce tool wear, extend coolant life, and improve both throughput and workpiece quality.

The trick, of course, is to apply the correct amount of coolant and maintain the right pressure and flow. So, depending on your application, a fixed rate unit may be adequate or you may be better served by a variable pressure system.

If you typically use one material and perform the same operations on an individual CNC machine, a fixed-rate system may be all you need. On the other hand, an automatic variable volume high-pressure coolant system is more versatile, as you can dial in the precise volume and pressure for virtually any machining application.

There are some other significant differences. While fixed rate systems pump at the same rate regardless of need, a variable pressure system uses only the amount of coolant necessary which saves energy, especially when using smaller tools. Variable high-pressure systems are more effective at controlling condensation and foaming that can affect the coolant temperature.

LNS Chipblaster applications specialists can help you determine the high-pressure system that best meets your needs. They can also provide information on the exclusive LNS Chipblaster CF-79 SA cyclonic filtration system that filters coolant to 2 microns and requires no filtering media or maintenance. For all the facts, contact your local LNS representative, call 814-724-6278 or email: hpsales@LNS-northamerica.com.