Turbo MF4

Compact chip conveyor with filtration to 50 microns

Key Featrues

Floor Space Utilization

The Turbo MF4 eliminates the need for extra floor space due to its compact design. Turbo MF4 is no larger than most standard hinge belt conveyors. This makes the MF4 ideal for factories with limited floor space and obstructions such as pillars, walls or with multiple machines side-to-side and/or back-to-back.

Maintenance and Hassel-Free Filtration

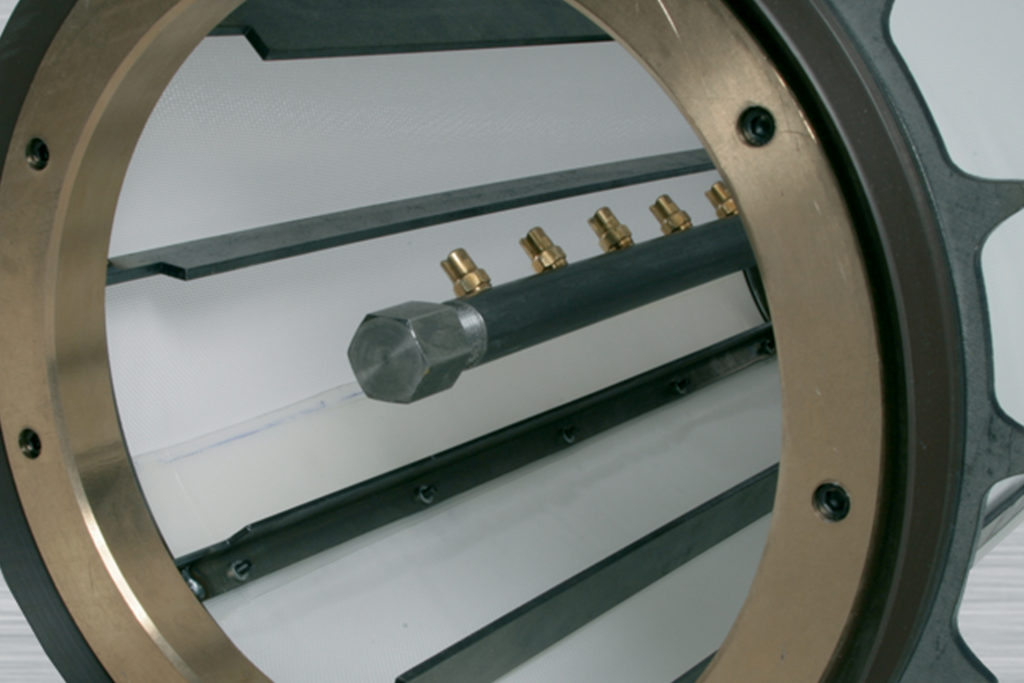

The self-cleaning filter drum located in the lower conveyor is protected from heavy chips by the upper conveyor and is designed with a very fine filter material which traps particles greater than 50 microns keeping all fine chips out of the coolant tank. The filter drum seal is a unique design incorporating Viton seal material and a metal pre-seal. The metal seal prevents chips from damaging the softer Viton material. The combination of these two seals creates a seal impervious to chip contamination, coolant degradation and wear.

Dual Purpose Conveying

The Turbo MF4 chip conveyor is designed and built to take on the toughest chip removal jobs and simultaneously provide superior filtration. The Turbo MF4 is a dual conveyor with a new compact design for reduced footprint. The upper conveyor is a hinge belt type which can be specified in standard or super heavy duty configurations to best match your chip load. The lower conveyor is a scraper type which removes the fines and small chips trapped in the lower conveyor. Coolant flows up to 150 GPM and is filtered with the standard filter drum design to 50 microns. The Coolant tank is configured to your requirements, depending on the machine tool design.

Choosing The Right Chip Conveyor

What are the various kinds of chip conveyors available?

There are several types of chip conveyors available, and each has unique characteristics that must be matched to specific requirements. Otherwise, the chip conveyor can malfunction with alarming regularity. Which means you’ll experience workflow interruptions and increased maintenance costs. And your productivity will suffer.

Surprisingly, there are many variables that you need to consider when adding a chip conveyor to a new machine tool or retrofitting an existing operation. And with the advent of multi-tasking machines that may produce several kinds and sizes of chips, the issue has become even more complex.

Turbo MF4 Chip Conveyor - Full product presentation

Watch this video to hear about the features and benefits of the Turbo MF4 chip conveyor and how it can enhance your machining processes.