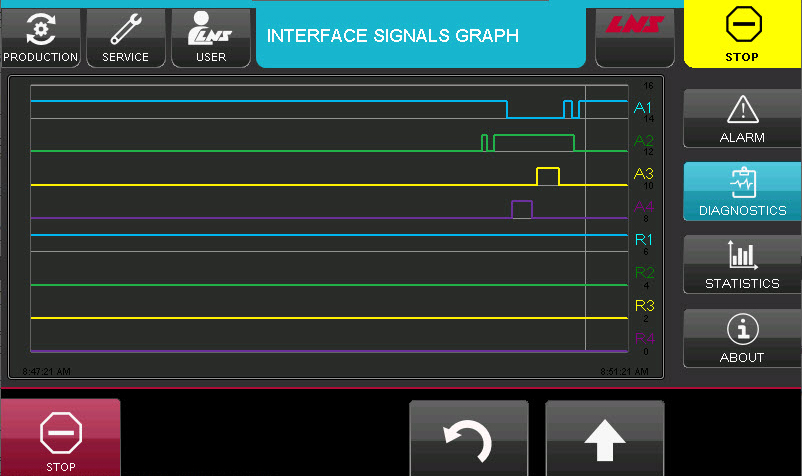

LNS Advanced HMI Enhances Machine Health Monitoring, Makes Programming & Troubleshooting Easier

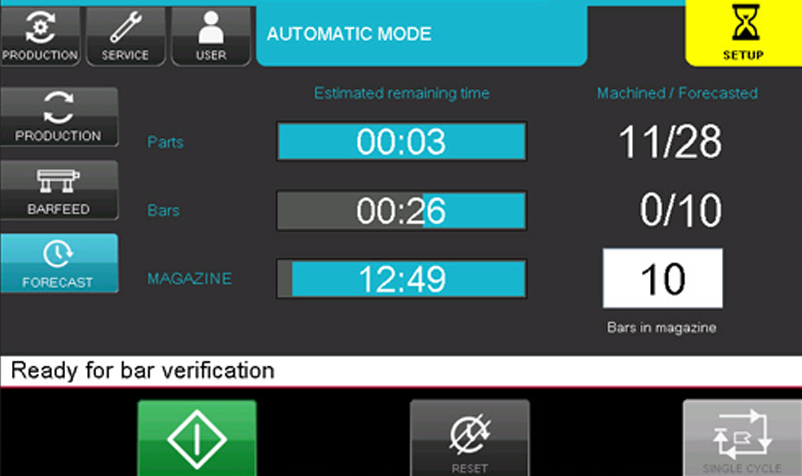

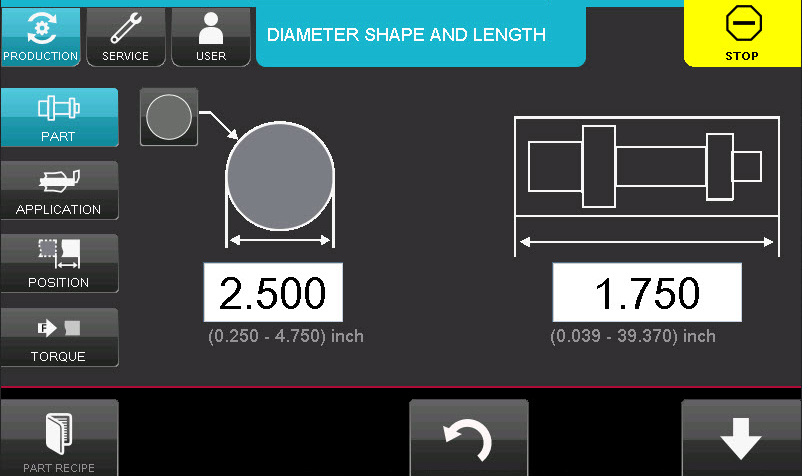

The user-friendly, ultra-light touch screen HMI with prompting menu screens ensures the interaction between the bar feeder and the lathe, allowing the production process to run safely and efficiently.