“The key to our working relationship with LNS is simply that they have knowledge, experience and excellent support. When one of our customers has a need for a steady rest system they come in, analyze the situation, put all the parts together and install exactly what is needed. The best part is this: I don’t have to worry about it. They know our standards, work closely with our people and provide whatever support we need.”

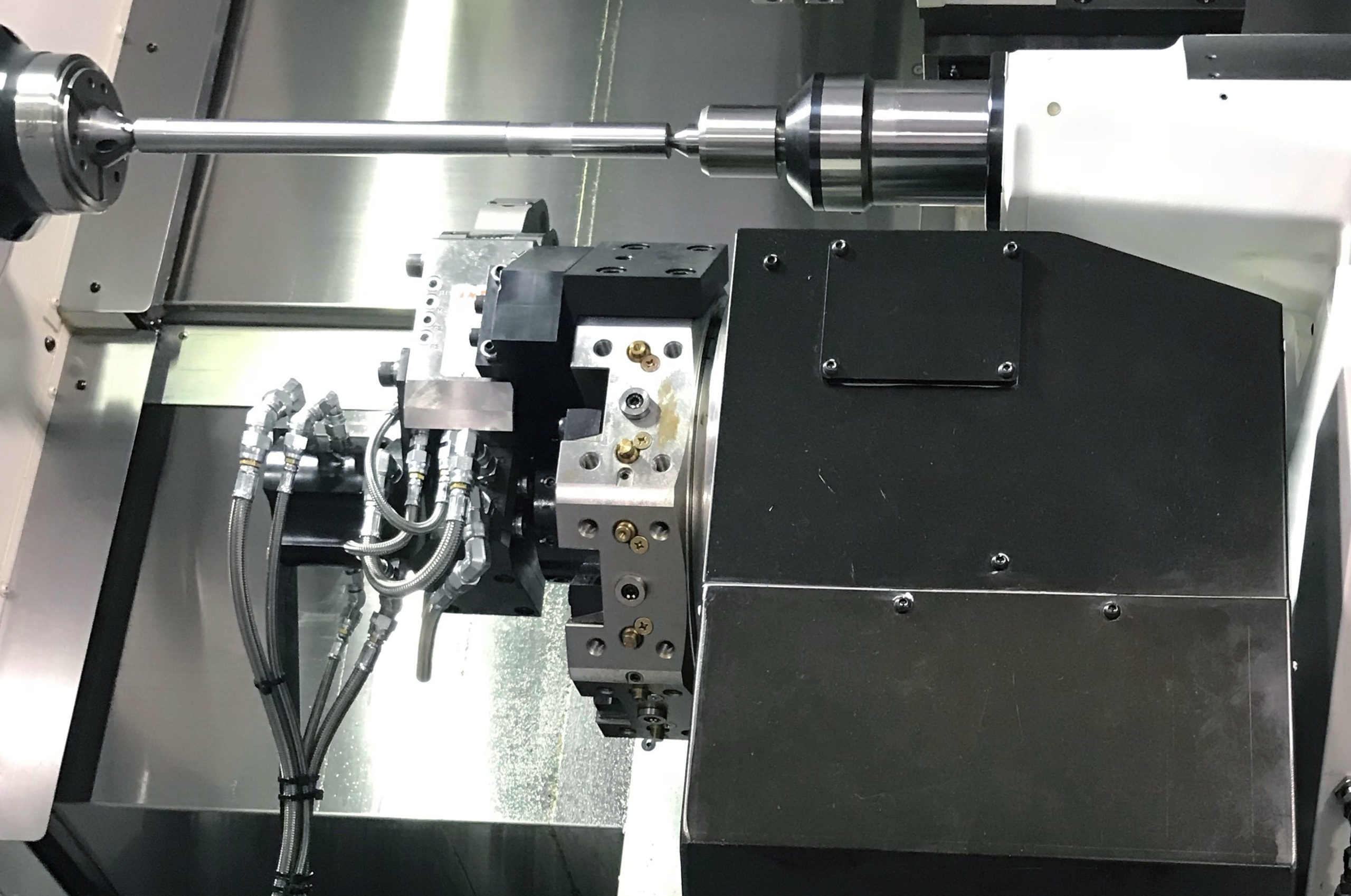

“One example involves gun barrels with very tight tolerances. Our customers need the support of a steady rest, but the machining performed on an Okuma LU 3000 turning center requires higher pressure for some operations and lower pressure for others. LNS provides valves for the steady rest that we configure with the CNC machine’s control to apply just the right amount of pressure for each operation. We also use LNS steady rests on the lower turrets as a follower to remove many of the “V” lines to provide a finer finish.”

“Our company has been around for over 80 years, so we understand the importance of experience and stability. We’ve found both in LNS throughout our 20 plus years working together.”

Andy Piccus, Head of Engineering and Contracts Administration

Robert E. Morris Company

LNS designs, manufactures, sells and supports air filtration systems, bar feeders, chip conveyors, Chipblaster coolant management systems, and work support devices worldwide. To learn more about LNS CNC machine tool peripherals, call 513-528-5674 or email: allproducts-sales@LNS-northamerica.com