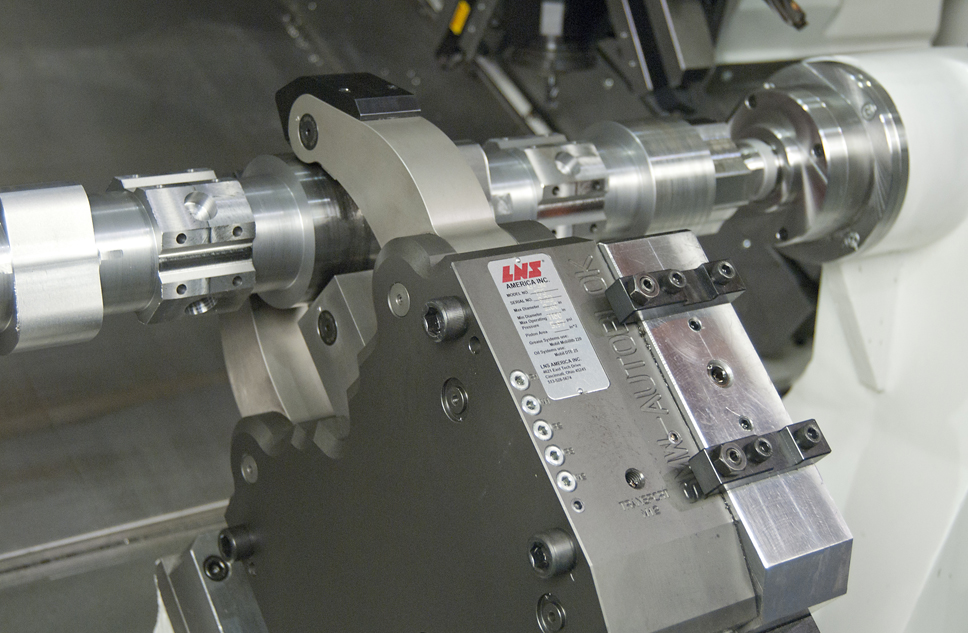

Steady rest workholding systems are essential for many applications, especially those involving long workpieces that are prone to deflection or part distortion. The steady rest provides greater control and stability that enables faster throughput while holding tight tolerances, improving part finishes and extending tool life.

This is true for turning, milling and secondary operations including ID drilling, boring and producing end face bolt-hole patterns.

Of course, every application has its own unique characteristics and, therefore, requires an equally unique workholding solution. This means designing a complete system built around the right type of steady rest.

Popular steady rests include the multi-purpose SLUX model that has a broad clamping range a sealed body and a proximity switch for end position open. The SR Premium model is equipped with coolant flush through the roller chip guards as is the K compact and RX Ultra compact steady rests that enable clamping of large parts in smaller CNC machines.

Whichever steady rest is best suited to an application can then be fitted with custom brackets, automatic clamp bases, valve packages, lubrication systems, hose track assemblies and protective way covers as needed to provide the most efficient service.

To learn more about LNS custom steady rest systems and other work holding, devices, contact your local LNS representative, call 513-528-5674 or email: SRsales@LNS-northamerica.com